|

| A 19th century Japanese Samurai demonstrates a balances of armament, mobility and protection. |

06/22/2016 - Iron Sights Productions The concept of protecting oneself from attack and counterattack is intuitive. Historical evidence of shields and armor carried by soldiers stretches back to the very beginning of human warfare.

It is only natural then that the introduction of mechanized warfare brought with it the ongoing evolutionary race to provide better protection in combat.

It is only natural then that the introduction of mechanized warfare brought with it the ongoing evolutionary race to provide better protection in combat.

Just as it was for footsoldiers, knights, and samurai attempting to balance protection with mobility, so to does mechanized warfare. The more armor a vehicle carries, the less mobile it will be. Balancing this equation so that any particular mechanized weapon system can fulfill its mission is the job faced by designers and engineers around the world.

Materials & Mobility.

Designers faced with the challenge of protecting mechanized units in combat were not starting from a blank slate. Throughout history, metal and composite materials have been used to protect against specific threats on the battlefield. When it came time to protect mechanized units on the battlefield, many of the same theories were applied and then expanded upon.

Early mechanized warfare featured steel plates. Through experience the optimal vehicle layout, the concept of sloping armor, and superior varieties of steel were discovered and developed further.

Today, tanks in particular, utilize composite armor which includes everything from layers of material, to internal scales and matrices under what otherwise looks like a homogeneous plate of armor. Everything from ceramics to depleted uranium has been employed to provide the densest amount of material for maximum protection without overly weighing down the vehicle.

Heavy tanks burdened by armor require serious engines. The struggle to balance armament, mobility, and protection has led to designers exploring everything from multiple engines powering a tank, to reducing the internal volume to almost inhuman proportions to save weight, to exploring the use of fuel-hungry turbine engines similar to those found in aviation.

There is more to armor than just a plate or plates of protective material. In addition to the armor itself, there is often coatings applied to its exterior and interior. Armor, even if it is not penetrated by an incoming weapon, can affect the crew inside the vechile in a phenomenon known as spalling. Spalling occurs when the inner-face of a vehicle's armor splinters upon impact, turning shards of material into small projectiles within the crew compartment. This can cause injury, fires, vehicle damage, and even death.

|

| Spall liners can be anything from a coating to a curtain. |

To minimize this problem, many armored vehicles include what is called a spall liner. This could be a coating applied to the inner-surface of a vehicle's armor, or even quite literally a material liner or curtain draped inside.

A famous example of coatings applied to the exterior of a vehicle's armor was Germany's use of Zimmerit. It was a paste applied in a textured fashion meant to make it difficult to adhere infantry carried magnetic anti-tank weapons to the side of German vehicles. The evolution of infantry anti-tank weapons toward rockets ultimately made Zimmerit obsolete.

Another kind of surface you will find on modern armored vehicles is non-slip coating. This, however, has more to do with making it easier for tank crews to move over the exterior of their vehicles than it does for protection.

Sloped & Reactive Armor.

Not only is the thickness and composition of an armored vehicle's protection important, but its orientation in relation to incoming fire. The legendary Russian T-34 medium tank manufactured between 1940-1958 had 47mm of upper-frontal armor. But when incoming enemy rounds struck the upper-frontal armor, because it was angled at 60 degrees, it would need to pass through 54 mm of steel.

Sloping armor increases the amount of steel a projectile must pass through.

During the Second World War and for a short period afterward, designers would attempt to take this concept to the extreme. Subsequent designs following the T-34 heavily featured sloping armor and a trend toward lowering the overall profile of vehicles. American and European counterparts likewise explored sloping to its evolutionary conclusion.

But with advances to sloping armor came advances in rounds designed to defeat it. In the end, the amount of physical armor a tank could carry into battle was unable to keep up with the penetrative power of anti-armor weapons.

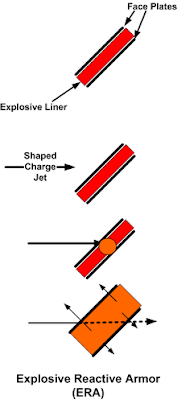

To solve this challenge, designers began developing reactive armor. Reactive armor contains explosives arranged in a variety of ways depending on what specific threats they are meant to defeat. When struck, they explode, creating an opposing force to an incoming projectile, diminishing or neutralizing its energy and preventing the vehicle's damage or destruction.

To solve this challenge, designers began developing reactive armor. Reactive armor contains explosives arranged in a variety of ways depending on what specific threats they are meant to defeat. When struck, they explode, creating an opposing force to an incoming projectile, diminishing or neutralizing its energy and preventing the vehicle's damage or destruction.Today, reactive armor has increased the RHAe (Rolled Homogeneous Armor Equivalent) to values sometimes exceeding a meter! In turn, anti-armor weapons seek to exceed even greater values. And with the advent of active protection systems, anti-armor rounds are defeated even before they make contact with the tank's armor, whatever it may be.

Active Protection Systems.

Designers of armored vehicles, when faced with the ability of anti-tank weapons to penetrate RHAe values of over a meter, seem to believe that the best way for armor to defeat an incoming round is to not be hit in the first place.

Thus, the advent of active protection systems.

These are systems that either confuse the guidance system of incoming anti-tank missiles like Russia's Shotora electro-optical infrared (IR) system, or identify and intercept incoming rounds of any kind with defensive rockets (as in Russia's Arena system) or blasts of directed metal shot (like Israel's Trophy system).

While it may seem that a curtain of impenetrable countermeasures backed by advanced composite armor may be more than match for anti-tank weapon, if history is any indicator, the evolutionary struggle between armor and anti-armor systems will continue well into the future.

-B for Iron Sights Productions

No comments:

Post a Comment